IPE WOOD DECKING INSTALLATION

and all Brazilian Hardwoods

Handling and Storage: Ipe is supplied partially air dried and should be stored out of direct sunlight and allowed to stabilize and acclimate to the installation environment humidity levels before installation. It is best to allow for ground side ventilation in the design as proper air circulation is necessary for long term stability of Ipe. When installing, allow 1/16″ gap between the deck boards for circulation of air. When Ipe is fully seasoned, shrinkage of approx. 1/16″ on 4″ wide boards to 1/8″ on 6″ wide boards may be expected.

Ipe Design

Recommended Ipe Spans: 16″ OC is the maximum recommended span for all 1×6 Brazilian Decking.

Always check with your local building code or an Engineer before starting your deck project. Many areas in Florida and Louisiana (and other southern states) will mandate deck and dock minimums.

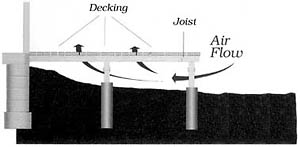

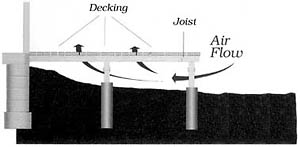

Ventilation:

The design of the installation must allow for adequate ground-side ventilation. Proper air circulation beneath the deck is critical to insure dimensional and mechanical stability of any IPE decking boards. Ventilation also helps reduce the potential for cupping.

Deck Spacing:

Some shrinkage will occur as the wood seasons and dries. The typical rate of shrinkage can be approximately 1/16” on 3/4 x 3-1/2” deck boards and 1/8” on 3/4 x 5-1/2 and 1 x 5-1/2 deck boards. (Please note: In hot, dry regions, shrinkage may exceed the averages). When installing Ipe deck boards during the winter season, when temperatures are below 40º, we suggest the boards be spaced with a 1/16” gap. Deck boards requiring straightening should be secured in the desired position until properly fastened. Screws may break if used to force boards into position.

Cutting and Drilling:

Use name brand carbide tipped saw blades and for smooth cuts due to the hardness of Ipe. Pre drill a pilot hole and countersink when using screws as fasteners.

End Sealing:

Ends should be sealed immediately after cutting using a clear aqueous wax end sealer to reduce end checking.

Fastening:

Boards should be pre-drilled to help prevent splitting of the wood by the fasteners and we suggest only the use of stainless steel fasteners for your Ipe decking installation.

Fasteners:

For residential and light duty commercial installations, we suggest the use of stainless steel Deckwise or Headcote screws, 2-1/2” minimum length. The heads of these screws are much smaller than the typical bugle-head screws required for softwood deck boards, and will be much less noticeable. When using the surface screw method, pre-drill pilot holes with a specially designed Smart-Bit. The Smart-Bit drills and counter-sink a perfect hole as it has a collar to prevent your drilling too deep. We suggest two (2) screws per joist when installing the deck boards. Always consult your local building codes for deck board fastening requirements.

Hidden Fasteners:

We carry several types of hidden fastening system. The grooved board systems are quicker to install and seem much easier than other systems. Unlike other hidden fasteners the grooved board systems are istalled completely from the top of the deck. Frequently decks are either high or very close to the ground. In these cases, a below deck hidden fastener would either require a ladder or laying on the ground. Either way it would require you to be constantly looking up and turning your head and neck into a cramped and un-natural position. The grooved board systems, being installed from the top of the deck requires no additional body strain. It also avoids moving ladders beneath a deck every few minutes.

Fastening:

Coated or galvanized steel fasteners may be used, but they tend to have a shorter life span and may cause staining of the wood. Stainless steel screws are considered the best and they will also eliminate potential chemical reactions or staining at the fastener location.

Insects:

All Brazilian decking is Resistant to Termites, Pine Beetles, Marine Borers.

Installing ipe hardwood decking can be a great addition to your outdoor space, as it is a durable and attractive wood option. Here’s a general guideline on how to install ipe hardwood decking:

Planning:

Depending upon your home and lifestyle you will first choose the best deck for your needs. Here are two main options. Most decks and outdoor kitchens are derived from these two major styles.

Covered Deck:

- Protection from the Elements: The big advantage of a covered deck is that it provides protection from weather including rain, snow, and intense sunlight. This means you can use the deck year-round.

- Screened from Bugs: This is huge for many areas of the country.

- Extended Usability: Since a covered deck offers protection, it extends the usability of your outdoor space. You can entertain guests, dine, or relax on the deck without worrying about the weather.

- Furniture and Decor: Covered decks often feature more comfortable and varied furniture and decor since they are shielded from the elements. You can have upholstered furniture and electrical outlets for lighting and appliances.

- Reduced Maintenance: Weather protection leads to reduced maintenance and longer-lasting materials.

- Increased Home Value: A covered deck can increase your home’s value as it adds functional living space that can be attractive to potential buyers.

Uncovered Deck:

- Natural Outdoor Experience: An uncovered deck provides a natural outdoor experience, allowing you to enjoy direct sunlight and open skies. It’s ideal for sunbathing, stargazing, and gardening.

- Lower Initial Cost: Building an uncovered deck is generally less expensive than constructing a covered one, as it requires fewer materials and no roof.

- Maintenance Considerations: Uncovered decks may require more maintenance, as the deck surface and furniture are exposed to the elements. You’ll need to refinish and reseal the wood more often.

- Seasonal Usage: While open decks are suitable for fair weather, they may be less usable during rainy or extremely hot conditions.

- Versatility: Uncovered decks can be versatile and flexible, allowing you to set up different outdoor configurations depending on your needs. They are great for gardening, grilling, and outdoor activities.

Building:

The hardness of ipe requires a few extra tools from the standard Pine or cedar deck.

Unique Tools You’ll Need:

- Stainless steel deck screws

- Ipe has tannin weep. MCQ Compliant screws will cause this. Use Stainless Steel

- Drill/driver

- Ipe is so hard you have to Pre-Drill for every screw

- Saw (circular or miter)

- Good Name Brand Carbide

- I prefer lots of teeth for a cleaner cut. However use what you have to see if it will meet your needs.

Installation Steps:

- Prepare the Substructure: This is the same as any Deck.

- Ensure that your deck’s substructure is solid and level. This typically involves constructing a framework of joists using pressure-treated lumber. Joists should be spaced according to your local building codes. Common Joist spacing is 16 inches.

- Ventilation

- Be sure you have air circulation below your Ipe or any decking. This will prevent cupping of your deck boards.

- Acclimate the Ipe Decking:

- Store the ipe decking boards in the area where they will be installed for at least a few days to allow them to acclimate to the local climate conditions. A week or more is best. The Ipe may have just been taken off a ship so you do not know the moisture content. Good airflow around the decking is critical during the acclimation time. Cover with a tarp to keep rain off but be sure to keep the ends open to the air.

- Spacing and Fastening:

- Use a spacer tool to maintain consistent gaps between the boards. Typically, a 1/8-inch gap is suitable for ipe decking.

- Secure each board to the joists with screws. Drive screws through the face of the board so they enter the joists beneath.

- If you desire a “no screws” look buy Brazilian Hardwood with side grooves. The Ipe Clip Extreme fasteners lock into the grooves and provide over 1000 pounds of holding power.

- Precision Cuts:

- Ipe Decking Installation (any Brazilian Hardwood installation) you need to seal all cut ends. This protects the ends from Checking (End Check) or cracking.

- This is done at the mill during production and you need to apply Ipe Seal or similar whenever you cut the end off an Ipe board.

- Finishing Touches:

- Once all the boards are installed, make sure all screws are countersunk and the surface is smooth. The Starborn Smart-Bit makes quick work and perfect countersinks.

- Finishing

- Ipe decking does not require staining or sealing. However, you can apply a UV-resistant finish if you want to maintain its natural color.

Maintaining:

While Ipe less maintenance compared to other wood species, it still benefits from some care to maintain its appearance and longevity.

- Regular Cleaning:

- Sweep the deck regularly to remove dirt, leaves, and debris. This prevents the buildup of organic material that can promote mold and mildew growth.

- Periodic Washing:

- Use a mild detergent or deck cleaner wash the deck surface periodically. Scrub gently with a brush or broom to remove any stains, dirt, or mold. Rinse thoroughly.

- Avoid Pressure Washing:

- Avoid using high-pressure washers on Ipe, as the force can damage the wood fibers and cause splintering. If you must use a pressure washer, keep it at a low pressure setting and maintain a safe distance.

- Oiling aka Finishing:

- While Ipe does not require sealing or staining for protection, many people choose to apply a UV-blocking finisher to maintain the wood’s natural color and prevent it from turning gray over time. UV Finishers are available in both Oil or Water based formulas. Both work about the same for color retention and longevity.

- Check for Loose Boards:

- Periodically check for loose or raised decking boards and secure them by reattaching them to the joists.

- Regular Inspections:

- Inspect your Ipe deck at least once a year for any signs of wear, damage, or loose fasteners.

- Be sure the Ground Supports do not have buildup of dirt that can retain moisture and cause rot

- Look at the joist and ledgers to insure they are all in good shape.

- Trim Nearby Vegetation:

- Trim overhanging branches or nearby vegetation to prevent excess moisture from accumulating on the deck.

Remember that Ipe decks will naturally age and turn silver-gray over time if left untreated. The Gray WILL NOT affect the longevity. Ipe will still last decades.

Frequently Asked Questions

ABS Wood has experienced builders for all customer facing positions. We have been on the jobsite. We have built it. If a customer has any questions, we are available to help. If we do not know the answers, we have a depth of resources to find out. Whatever happens ABS Wood is here to help.

Deck Fasteners tend to fall into 2 categories; hidden and face screws. Conventional Face screws are commonly used. With Brazilian Hardwoods only use Stainless Steel. The MCQ Compliant screws will cause tannin weep. This will look like rust stains. Only stainless prevents this occurrence. If a customer desires the hidden look, then Ipe Clip Extreme is the fastener of choice. The Ipe Clip Extreme has stronger holding power than most any other hidden faster. In addition, it keeps the boards straight as the deck ages. Other clips allow the boards to “slip out” from under the fasteners. Ipe Clip Extreme holds the boards in place preventing slip out.

Brazilian woods like Ipe, will last for decades. It does not rot, termites and pine beetles will not attack it, it will not decay. The labour to install a deck in comparable no matter what decking you use. However, unlike Pine, Cedar or other common deck materials, Brazilians will last. This will stretch out your investment for a much longer time.